Unclear Batteries.

Clear Insights.

Technologically unmatched. With AI-powered models we decode what others can't even see. Our independent, in-depth battery diagnostics create confidence in every EV decision – fact-based, fast, and precise.

Assurance

in one easy step

Check the condition of your battery in just three minutes – independently, accurately, and manufacturer-independent. Order the AVILOO FLASH Test now and get clarity at a glance.

AVILOO is trusted by leading companies

News from the E-Insider

Tested assurance

AVILOO CERTIFIED

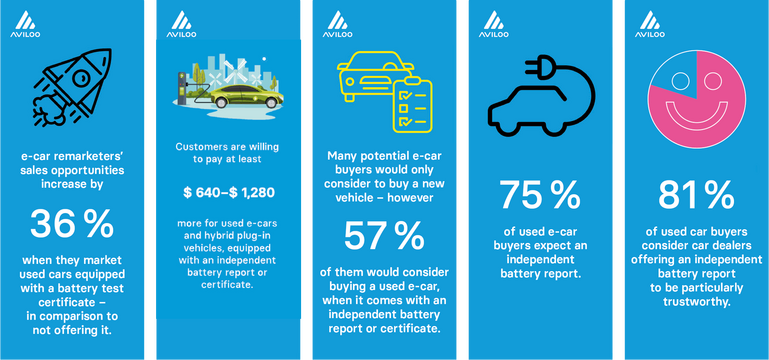

Certificate = Assurance = Sales

The AVILOO Battery Certificate makes car batteries a matter of trust. Whether you are buying, selling, or leasing an electric car, clear facts provide assurance and increase the value of the vehicle.

battery evaluation

sales value

Global standard for battery diagnostics

AVILOO is the market leader in independent battery testing, setting itself apart from conventional battery readouts. Not only in Europe, but worldwide, we set standards in transparency, trust, and value determination for electric cars. Our market presence extends from the US to Mexico and Brazil to South Korea, Japan, and Australia, and we are continuously expanding our network.

Upcoming Events

Do you have any

questions?

Some questions come up again and again. If you're unable to find your question, we will be happy to assist you personally:

You can check which vehicle models are approved for the AVILOO FLASH Test or AVILOO PREMIUM Test in our database:

We are constantly expanding the list and regularly adding new models.

No – you don't need any special knowledge. We'll give you all the info, documents, and instructions you need. Plus, our support team is always ready to help by email or phone.

The AVILOO FLASH Test is designed as a plug-and-play solution and can be easily integrated into existing processes. Installation takes only a few minutes – after that, the test runs in the background during normal vehicle operation.

Yes – we provide business customers with an online dashboard where you can easily manage, download, and evaluate all tests performed, vehicle data, and certificates. An API connection to your system is also available on request.

No. Regardless of the reason why multiple tests were performed on a vehicle within two hours, only one test per vehicle use will be charged. You will receive a single invoice for the VIN in question.

Yes! We regularly offer free live demonstrations and webinars. Just give us a call or send us an email, and we will find a suitable date:

Yes – the AVILOO Battery Certificate can be seamlessly integrated into existing vehicle exchanges, sales platforms, or internal remarketing systems via API. This allows the battery state to be displayed directly in the listing – for greater transparency, trust, and higher closing rates.

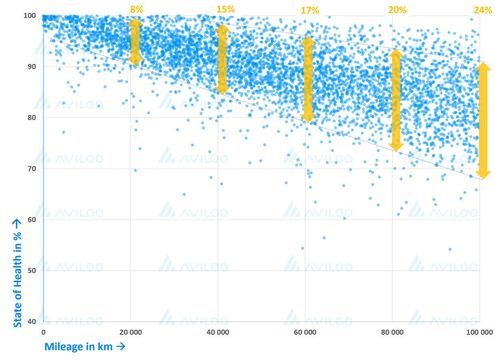

An independent battery certificate provides objective assurance about the condition of the most important vehicle component – the battery. Studies and market analyses show that vehicles with documented battery health achieve higher sales prices and sell faster, especially electric cars with a good SoH rating.

Yes – the AVILOO FLASH Test is scalable and ideal for use in fleets, lease returns or used car inventories. For larger quantities, we offer customized processes, logistics solutions, and evaluations, including a dashboard overview and API connection.

The FLASH Test provides a quick assessment of the battery's state within 3 minutes – ideal for fleets and remarketing. The AVILOO PREMIUM Test analyzes the battery over a complete discharge cycle and provides the most detailed assessment – including SoH, range and certificate. The FLASH test accuracy is approx. ±3% compared to the PREMIUM Test.

The QR code on the printed AVILOO Battery Certificate leads directly to the original digital version on the AVILOO website. By comparing the digital and printed data, the authenticity of the certificate can be clearly verified.

The State of Health (SoH) read by the battery management system (BMS) is based on manufacturer-specific algorithms and can differ significantly from the actual state of the battery – sometimes being too high or too low. The AVILOO Certificate, on the other hand, provides an independent, objective assessment of the battery state based on a comprehensive technical analysis. It not only determines the actual SoH, but also checks the battery down to the individual cell level for possible defects and anomalies. Soon, each AVILOO Certificate will also include a visual heatmap showing the condition of every cell and highlighting any irregularities. This provides a complete picture of the functionality and safety of high-voltage batteries.